7BBL bright beer tank is manufactured by ZR BREW,we can customize beer fermentation tanks of different specifications according to customer needs. All fermentation tanks are made of certified 304 or 316 stainless steel materials and components, 100% TIG welding and hygienic polishing,to ensure food hygiene level, and strictly undergo strict production process Quality control, inspectionp; and pressure testing, form detailed inspection records, and send out with the goods. ZR BREW guarantees free delivery of all valves and fittings.

Product Paramenters

| Interior | Jacket | |

| Material | SUS304 | SUS304 |

| Working pressure (Mpa) | 0.2 (30psi) | 0.2(30psi) |

| Design pressure (Mpa) | 0.3 (45psi) | 0.4 (60psi) |

| Effective volume | 7BBL | |

| Total volume | 8.4BBL | |

| Tank Size (mm) | Ø1160*2200 | |

| Cooling meth | Glycol water cooling | |

| Insulation material | Polyurethane | |

| Insulation thickness(mm) | 80 | |

| Inter tank thickness (mm) | 3.0 | |

| Outer tank thickness(mm) | 2.0 | |

| Note:1Barrel (BBL) =117 Liter 1Hl=100 Liter 1Gallon=3.7854 Liter 145psi=1MPa | ||

Details Images

|  |  |  |  |

| Mechanical PRV | Sample Valve | Pressure manhole | Ladder hook | Safety valve |

|  |  |  |  |

| Titanium Rods | Temperature Sensor | Solenoid valve | Level gauge | Adjusting bolt |

7BBL bright beer tank standard configuration

Dished and conical head are available

Pressure side manhole door

TC connected CIP arm with 360° coverage spraying ball

Sanitary sample valve

Safety valve on top

Mechanical safe valve PVRV 2 bar on CIP arm

Diaphragm pressure gauge on CIP arm

Tri clamp discharge arm with butterfly valve

Carbonation stone for CO2

Liquid level display on the sidewall

Thermowell for high accuracy temperature sensor

Top hooks for hanging ladders

4pcs completely SUS304 heavy duty legs with leveling pad and legs support

Complete valves, fittings and all parts

100% TIG welding with pure argon gas shield

Interior Finish: Sanitary 2B finish, Pickled and Passivated; (8K Mirror finish optional)

Exterior Finish: Oil brushed finish(2B, 8K Mirror finish optional)

Interior full polished to 0.2~0.4 μm without dead corner

Glycol Jacket: Dimpled plate on cone and side

7BBL bright beer tank optional configuration

Separate blow-off pipe & CIP

Display temperature gauge in front

Advantage of configuration

Polishing/drawing/mirror finish/pickling passivation optional

Shadowless manholes or top manholes depending on the customer's fermentation process and brewing type.

The headspace is larger, and the covering headspace volume is calculated separately and additionally.

Jacket test by water and gas, 5bar/75psi for 1hour, 3.5bar/52psi for 48 hours,Tank leakage test by water and gas, 4bar/60psi for 1hour, 2.5bar/37.5psi for 48 hours,all data will be recorded to facilitate strict quality control and management

Easy to operate with dedicated ladder

For easy lifting, it is equipped with lifting lugs.

For flexible conveying of beer, it is equipped with a swivel rocker

To ensure tank alignment and leveling, it is equipped with adjustment bolts

Specifications and models

| Sepcification selection | Total volume(L) | Cooling ares(m2) | Diameter(mm) | Height |

| ZR-BBT-100 | 120 | 0.86 | 650 | 1500 |

| ZR-BBT-200 | 240 | 1.3 | 850 | 1600 |

| ZR-BBT-300 | 360 | 1.9 | 860 | 2000 |

| ZR-BBT-400 | 480 | 2.1 | 960 | 2000 |

| ZR-BBT-500 | 600 | 2.2 | 960 | 2200 |

| ZR-BBT-1000 | 1200 | 3.4 | 1260 | 2600 |

| ZR-BBT-1500 | 1800 | 4.5 | 1460 | 2850 |

| ZR-BBT-2000 | 2400 | 5.4 | 1600 | 3100 |

| ZR-BBT-2500 | 3000 | 6.0 | 1800 | 3400 |

| ZR-BBT-3000 | 3600 | 6.7 | 1800 | 3600 |

| ZR-BBT-4000 | 4800 | 7.6 | 1900 | 4000 |

| ZR-BBT-5000 | 6000 | 8.5 | 2200 | 3800 |

Our service

| Pre-sale service : | After- sale service: |

1. Free turnkey beer brewing/filling/packaging solutions. | 1. Perfect packaging and transportation, all the tanks are wrapped by three layers of PE protective film, the nozzles are blocked by dust caps, the spare parts are sealed in wooden boxes, the whole loading process is recorded by photos, and accompanied by a checklist, sent to you together. |

2. The technical team with 13 years of experience in the beer brewing equipment industry, one-to-one service, provides different brewing process according to your requirements. | 2. Complete installation and commissioning services, providing detailed installation instructions in English or French, online video-guided installation and offline door-to-door installation. You can choose between two installation and commissioning modes. We are also establishing technical service teams around the world, so that you can look back worry-free. |

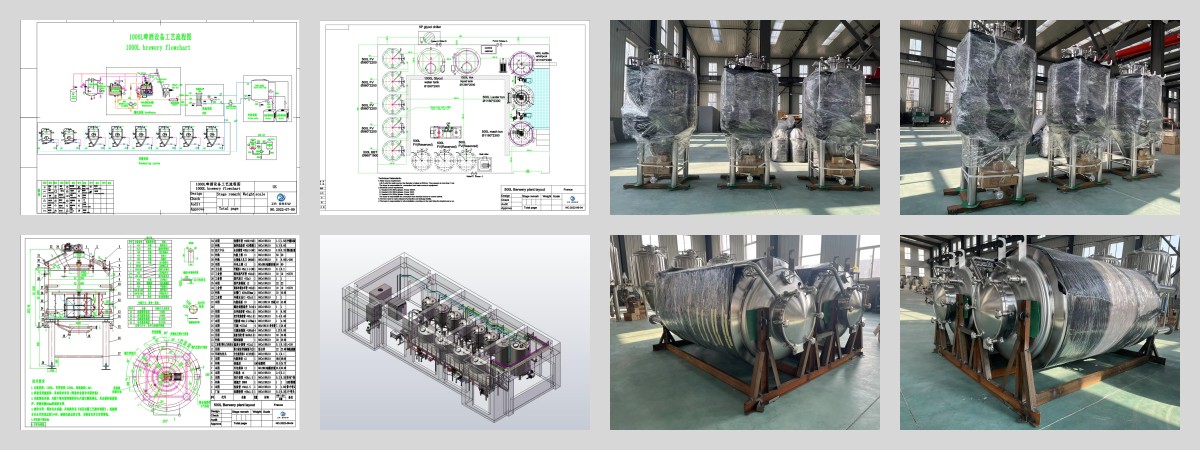

3. According to your site, carry out overall project planning and provide two-dimensional and three-dimensional layout drawings. | 3. Lifetime warranty and technical consultation. |

Why choose ZR BREW

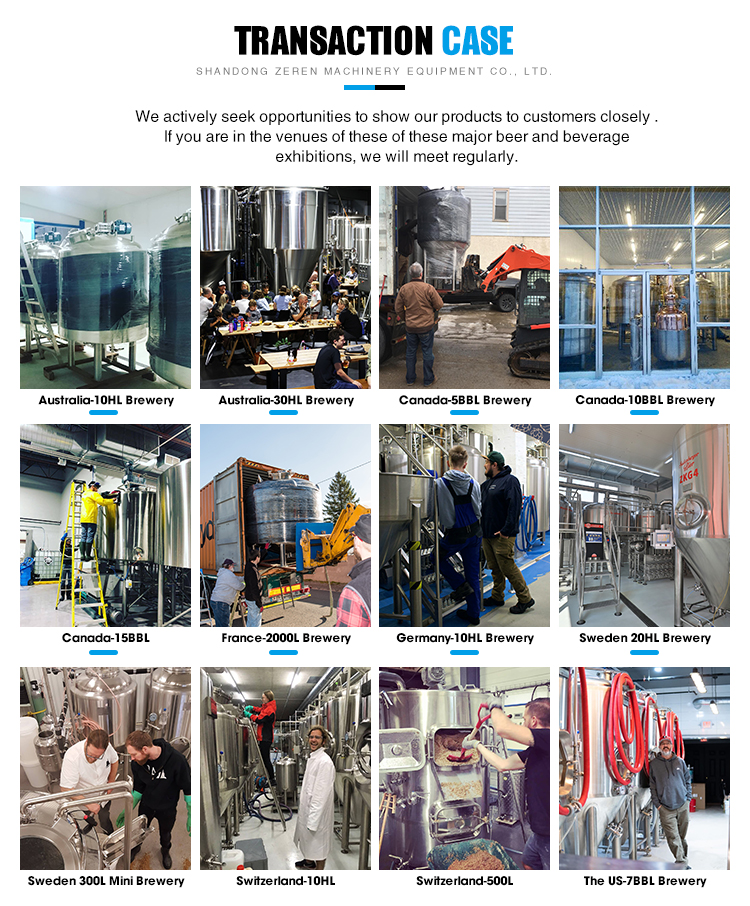

Shandong Zeren Machinery Equipment Co., Ltd. referred to as ZR BREW.ZR BREW is an equipment manufacturer

focusing on the biological fermentation industry, mainly engaged in beer brewing equipment, providing high-end

comprehensive services of product design, production, processing, installation, technical process training. ZR BREW's

products have been exported to more than 40 countries and regions in the world.

ZR BREW Company is located in Jinan City, and the factory is located in Dezhou City, covering an area of 10,000

square meters. The company has 52 employees, including 6 senior technicians and 8 intermediate technicians, with

more than 20 undergraduates. Project leaders and technical engineers have more than 13 years of work experience

in the beer industry.

Our Advantage

Our Team

Certifications

Comment contrôler la température du fermenteur

L'automate ou l'afficheur numérique est connecté au capteur de température PT100 installé sur le réservoir via la ligne de signal pour contrôler la température.

Comment utiliser votre fermenteur ?

ZR BREW a des instructions papier en anglais, et nous vous enseignerons jusqu'à ce que vous le fassiez bien.

Quel est votre délai de paiement ?

1. Transfert T/T, paiement anticipé de 40 % pour le démarrage de la production, après paiement du solde de 60 % pour l'expédition. 2. Paypal ou assurance commerciale est disponible.

Combien de temps dure le délai de livraison de votre fermenteur ?

Habituellement, le délai d'exécution pour le réservoir de fermentation est de 30 jours ouvrables, tandis que le délai d'exécution pour le projet de brasserie complet est de 40 jours ouvrables, chronométré à partir du dessin final confirmé

Assurez-vous un service après-vente ?

Oui, ZR BREW pourrait fournir un service après-vente. Nous avons de nombreux ingénieurs professionnels, ils peuvent se rendre chez vous et enseigner à votre personne l'installation et le brassage.

Shandong Zeren Machinery Equipment Co., Ltd. est un fabricant d'équipements spécialisé dans l'industrie de la fermentation biologique

Copyright © Shandong Zeren Machinery Equipment Co., Ltd. Tous droits réservés |

Plan du site

| Soutien technique: